Expertise

Cast Iron CAD has worked on a wide variety of industries for a diverse range of clients. We are extremely adaptable and our team of design engineers can find a solution to almost any kind of challenge. Find out more about some of our expertise & services below.

Design & engineer

Design > Optimisation > Prototypes > Testing

Production

Production engineering > Assembly methods

Project management

Idea > Engineer > Production > Fulfillment

Optional project services:

- Product lifetime support

- Compliance and safety (CE)

- Consultation & University seminars

- Patents and design rights (IP)

- Funding applications

Optional production services:

- Manufacturing & assembly

- Supply chain management

- Inspection of manufacturing facilities

- Production routing

- MRP/ERP system design

- Quality control documentation

Optional design & engineering services:

- Marketing renders

- Finite Element Analysis (FEA)

- Line art for patents

Production engineering methods

Design, Engineering & Production Techniques used:

CIC works with all industrial manufacturing techniques:

Polymer Engineering:

Advanced polymer product development

Areas of expertise:

Injection

molding (RIM, MIM, blowing agent foamed), Extrusion (multiple layer,

straight profile), Blow-molding, Sheet thermoforming (vacuum,

pressurized), Thermosetting compounds (compression, transfer molding,

casting), rubber molding, 3D Printing (SLA, SLS, CLIP), Foam Sheet &

punching, Rotational Molding, CNC machining (multiple axis, lathe),

joining (vibration welding, gluing, assembly, snap-fit), surface

finishing.

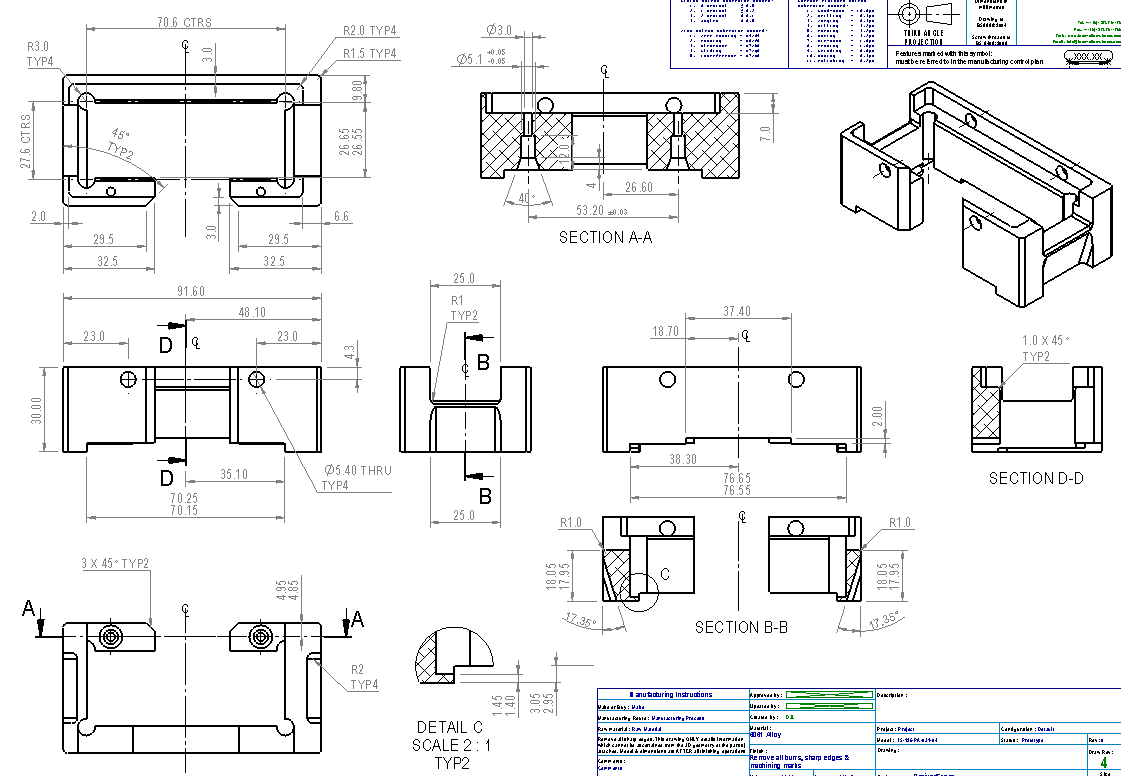

Metalwork:

CNC machining (multiple axis,

lathe), casting (lost wax, sand casting, shell molding), Fabrication

(welding, brazing, gluing, riveting, Soldering, assembly, fusion),

Finishing (grinding, hand polishing, electro-polishing, coating (paint,

electroplating, galvanising), extrusion, rolling, bending, cutting

(laser, water, punching), pressing, tempering, engraving, spinning,

swaging.

Ceramics:

CNC machining (multiple axis, lathe), injection molding via sintering.

Woodworking:

Handcrafted,

CNC milled, lathe, finishing (polished, painted, hot stamping, laser

etching) Joining (assembly, standard joints, gluing), routing

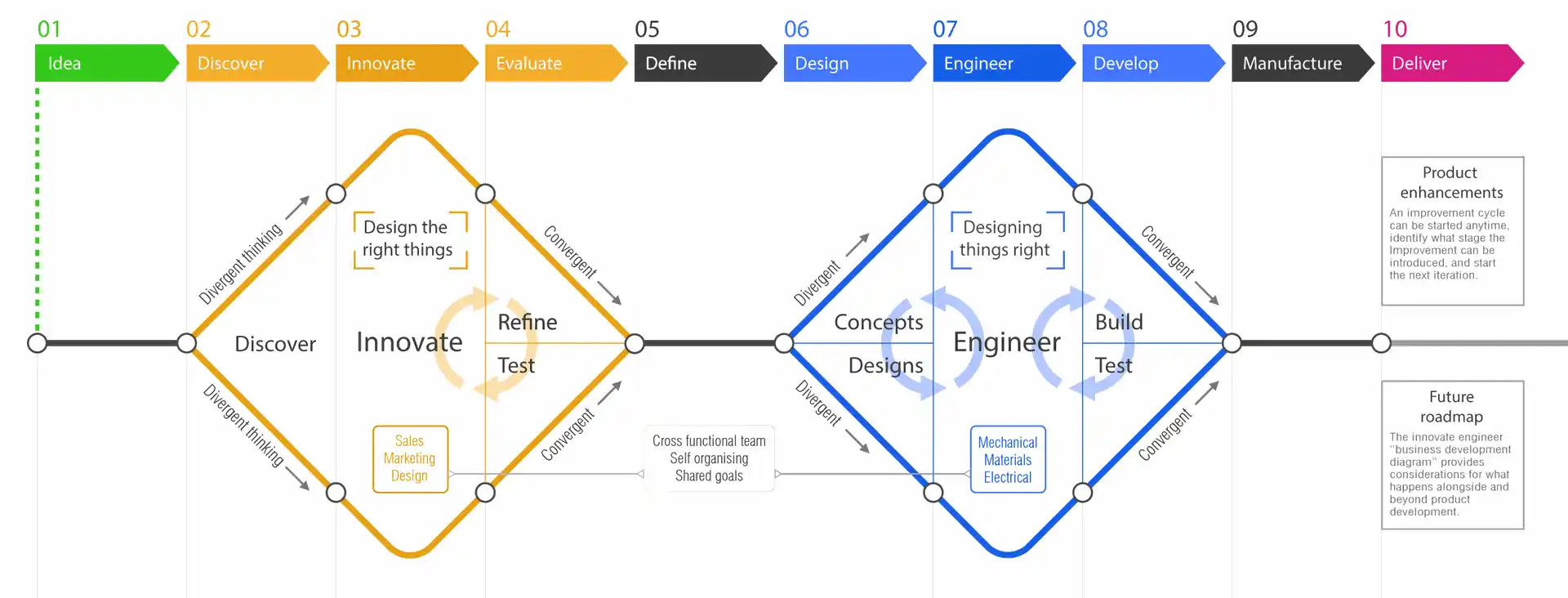

Chart of activities

The innovate.engineer diagram shows a "chart of activities" at its base, so far, after developing over 260 products this has proved to be a comprehensive way of accounting for all the activities worked on when working from idea to distribution, part of project scoping is highlighting which of these activities are required as the project moves forward. This not only highlights the project plan, but can also highlight some items that have been skipped along the way, giving clarity to the project, and keeping expectations aligned.

02. Discover

Identify "Value goals"

Understand industry

Customer persona

Market context enquiry

Establish IP strategy

Stakeholder and user interviews

Brainstorming

03. Innovate

Impact mapping

Group ideas

Evaluate priorities

Affinity diagram

Target audience

Technology research

Sustainability

Market research

Focus groups

04. Evaluate

Competitor review

Market analysis

Risk Assessment

Confirmation bias

User workshops

Product themes/types

MVP

Value proposition canvas

Products and services

Gain creators

Pain relievers

Value propositions

Customer segments

Business model canvas

Key partners

Key activities

key resources

Customer relationships

Channels

Revenue Streams

Cost structure

05. Define

Design Brief

Specification details

Moodboard

Timeline & investment

RRP & quantity estimation

06. Design

Brainstorming

Sketching

Mechanical concepts

Electronic concepts

Branding

Concept 3D CAD

Basic 2D drafting

Marketing renders

Packaging design

Funding research

Competing products

07. Engineer

Construction CAD 2D/3D

Technology review

Materials research

Mechanical analysis

Electrical engineering

Engineering CAD

Engineering drawings

Patent documentation

Industry standards

FMEA

CE UKCA paperwork

CAD pre-production

Record iterations and developments

08. Develop

Proof of concept models

Presentation model

Functional

Pre-production

Production prototype

Focus group*

A/B testing

Fit Form Function

User Testing

CE UKCA extreme testing

Manufacture

The business part: Production-ready documents, quality control, assembly & API to our MRP system.

09. Manufacture

Production 3D CAD

Production drawings

Production methods

Quality control documents

Assembly methods

PLM system

Routing & instructions

Packaging

Master production schedule

MRP system

10. Deliver

Sales forecasts*

Product launch costs

Marketing feedback*

CRM system*

Supply chain management - Fulfillment

International Standards

Product Insurance*

Customs *

Sales API link to MRP

*External service to CIC Ltd

Get in touch

If all this sounds perfect for the idea you are working on please feel free to get in touch and tell us a little about the product you are looking to develop.